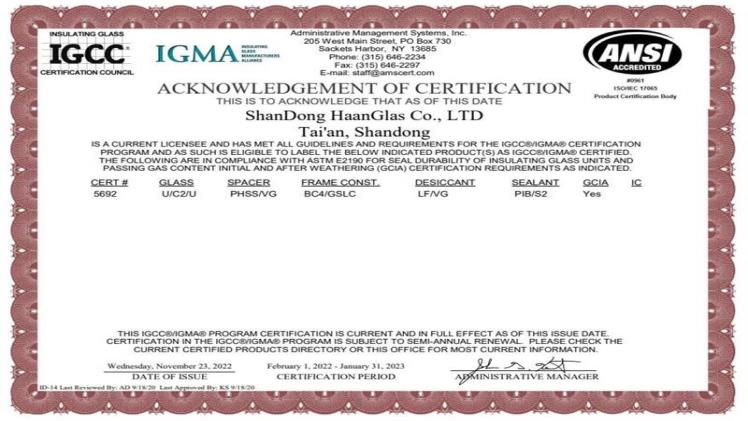

SGCC/IGCC Certified Vacuum Glazing

In order to be certified vacuum glazing, the glass must pass the standards set by the IGCC (International Glazing Certification Council) and the SGCC (Standard Glass Certification Council). This is a third-party certification, which guarantees that the glass is safe for use.

ASTM C1036-11e1 Standard Specification For Flat Glass

The ASTM C1036-11e1 Standard Specification for Flat Glass is a standard covering flat glass, insulating glass units, tinted glass, clear glass, and solar/optical properties. It contains testing protocols and laboratory and field evaluations. This specification covers laminated architectural flat glass and heat-treated flat glass. It also covers glazing products for exterior and interior single-pane windows, mirrors, and spandrel glass. To know more click Louis Vuitton Handbags

The ASTM C1036-11e1 Flat Glass Specification is a useful guide for designers and architects when selecting glazing products. It specifies the thickness, type of interlayer, and interlayer color of a laminated glass unit. In addition, it includes glazing materials, accessories, and other pertinent information. When designing or evaluating glazing products, it is important to evaluate the visual performance of the glazing, including distortion, UV absorption, light transmission, reflectivity, and clarity. Depending on the project, building teams may define key visual criteria for architectural glass ceramics.

SGCC/IGCC Certified Hybrid VIG

Hybrid vacuum glazing is a novel glazing system which combines vacuum and CO2 gas gaps. It has the potential to reduce energy consumption in buildings by absorbing greenhouse gases. In addition to reducing glazing U-value, this innovative technology has the potential to provide soundproof performance.

SGCC/IGCC certified vacuum glazing has proven its safety, making it a valuable asset to new construction and historical renovation. Unlike traditional insulating glass units, it also has excellent thermal conductivity, thereby eliminating condensation and improving overall soundproof performance.

This innovative technology can be incorporated into any type of glazing system. Specifically, it consists of two lites of 4mm glass which are separated by a non-leaded proprietary metal seal. The unit is light and extremely slim. Compared to traditional IGU components, it offers 36dBS soundproof performance and delivers thermal insulation performance up to 14 times greater than monolithic glass.

ASTM E1300 Standard Practice for Determining Load Resistance Of Glass In Buildings

The ASTM E1300 Standard Practice for Determining Load Resistance of Glass in Buildings provides a set of methods for evaluating the load resistance of glass in buildings. These procedures apply to a wide range of glass constructions. They are used to determine whether a glass is resistant to a specified design load.

ASTM E1300 is the primary reference for specifying glass for use in building envelopes. It defines the load resistance of glass constructions, provides a methodology for testing and analyzing the strength of a glass construction, and includes the results of tests.

The practice covers a variety of glass types, including monolithic glass, laminated glass, insulated glass, triple-glazed IG units, and asymmetric IG units. In addition to providing load resistance, the standard also describes the effects of various environmental conditions on the strength of the glass.

Absorptive Electrochromic Coating On A Gla

In the insulated glass unit (IGU) for buildings, electrochromic coatings (ECC) limit solar heat gain and radiation. The useful life of IGUs with absorptive ECC may depend on how well they maintain acceptable uniformity.

Electrochromic devices can change between clear, dark, and tinted states. These changes are achieved when an electrical current is applied to the device. A typical electrochromic device can be a rectangular shape, but can be of any size or shape.

The electrochromic window test is a test method to measure the uniformity of an absorptive electrochromic coating on a glazing surface. It includes one or more active layers, transparent conducting electrodes, and evaluation criteria. This test method is also used in combination with other testing methods to evaluate the performance of ECCs in a particular application.

IGCC Certification Is A Third-Party Verification That Tthe Glass Is Safe To Use

When you use the safety glazing materials certified by the Safety Glazing Certification Council (SGCC), you can be sure that you are getting safe glass. It is an independent, non-profit corporation that certifies safety glass products and other glazing materials. The SGCC conducts annual audits of certification programs, and samples are tested twice a year.

Vacuum double glazing units is an ongoing effort to improve the quality of insulating glass units and other insulated glass products. Products that meet or exceed the IGCC/IGMA specifications are awarded a certification number. This number allows you to identify the manufacturer and identifies the product.

The IGCC/IGMA certificate requires that the insulating glass unit have an electrochromic system. Electrochromic systems are required to meet or exceed the ASTM E2141/chromic fenestration standard. A third party test laboratory must verify the product’s compliance with this standard.

Last Word

Vacuum glazing is a glass product for windows, which offers improved comfort, better energy efficiency and lessened costs on thick windows. It can be incorporated into conventional window frames without modifying the original frame.